We manufacture an array of products to provide you one-window comprehensive solutions to all kinds of packaging requirements.

-

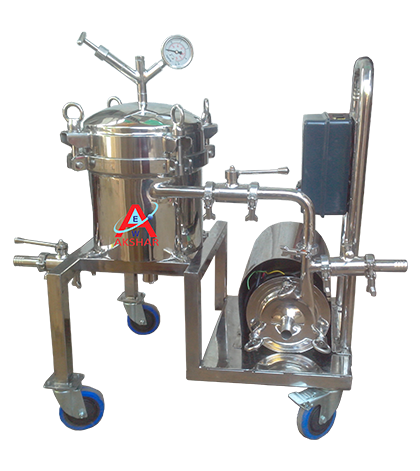

SPARKLER - STANDARD FILTER PRESS

8” x 6 PLATES – 400 LPH FLOW RATE 300-25000 LPH

-

HORIZONTAL FILTER PRESS

8” x 6 PLATES – 400 LPH

We are Akshar Engineering Works established in 1996, are one of the precursor firms influential in manufacturing, supplying, exporting wide array of Pharmaceuticals Machinery. Our offered types of products include Sparkler Filter Press, Zero Hold Up Filter Press and Filter Press Filtration Machine. We have attained wide acceptance in the market for implementing progressive technology for fabrication of these machines. These products are much appreciated in the market for sturdiness, precise finishing and superior functionality traits. With the fabrication being done by using quality-tested raw materials, these machines are available with us in wide preferences.

Our company has embarked on this domain with great achievements under the guidance of Mr. Vishal Panchal. The prime focus on delivering quality and ensuring ethics at all levels of client dealing has earned us a respectable global customer base.

With the aim of employing maximum precision functionality in our products, we have developed high-end infrastructure system. With the potent use of machinery in advanced manufacturing facility, we are able to fabricate different types of machines thus serving diversified demands of customers. Our products range fulfills the every parameters of quality for gaining maximum output of them. Moreover, we make the supply of these machines to customers in durable packaging at nominal price range. We utilize a team of hard working personnel who ensures the highest level of quality production. Owing to these attributes, we cater to variegated needs of clients globally with uttermost perfection.

- About Product

- Salient Features

- Optional Features

- Technical Specifications

- Applications

- E-Brochure

- Gallery

The Akshar Engineering Works offer a wide range of Standard filter press in India consisting of stainless steel shells with bolted top cover. This feature helps the filter press to create and maintain its pressure. Several disc type filter plates are arranged horizontally in the filter cartridge assembly with perforated supporting screens, filter media and interlocking cups. The whole assembly shell stands on S.S. trolley and structured with pump and piping connection.

Operations

The main operation of horizontal standard filter press is to filter the impure liquid. Arriving on top of each horizontal plate with increasing pressure, the filter media holds back the impurities and allows the filter to pass through centre by interlocking cups, which takes the filtrate to the outlet of the filter. The cake formed between the horizontal plates can also be obtained. The function of filtration process becomes slow when the liquid reached its holding capacity into the cake.

- GMP model stands on SS trolley

- Manufactured using quality raw material such as S.S. 304/316/316L M.O.C

- Having M.S./S.S. Jacket for hot filtration

- Available in various sizes and different diameters having numerous number of plates

- It also provides the Back wash facility for continuous operations.

- Two filter plates are available – Deep and Shallow

- The horizontal type filter plates prevent the cake dropping from the shell.

- 8”, 14”, 18”, 24”, 33”.

- SS 304 Double Jacketed for Hot Filtration.

- Flame Proof Motors & Starters

- 3 Phase & single Phase motors available

- Centrifugal , Gear pump, Lobe pump for different filtration liquid.

- Compounding Pressure Gauge, Air Valve & Safety Valve

| Model No | Dia of Plates (inches) | No of Plates | Heights of Plates (mm) | Filtration Area (Sq. Mtr.) | Cake Holding Capacity (rf^) | Flow Rate ~ (ltrs/hr) | Size of Pump | Motor (hp) |

|---|---|---|---|---|---|---|---|---|

| ASFP84 | 8 | 4 | 25 | 0.132 | 2.5 | 300 | 0.5" | 1.0 |

| ASFP86 | 8 | 6 | 25 | 0.198 | 3.9 | 400 | 0.5" | 1.0 |

| ASFP88 | 8 | 8 | 25 | 0.254 | 4.95 | 500 | 0.5" | 1.0 |

| ASFP144 | 14 | 4 | 38 | 0.378 | 12.9 | 700 | 1.0" | 2.0 |

| ASFP146 | 14 | 6 | 38 | 0.567 | 17.2 | 1200 | 1.0" | 2.0 |

| ASFP148 | 14 | 8 | 38 | 0.756 | 23.5 | 1600 | 1.0" | 2.0 |

| ASFP1410 | 14 | 10 | 38 | 0.924 | 27.5 | 2000 | 1.0" | 2.0 |

| ASFP1412 | 14 | 12 | 38 | 1.156 | 29.95 | 2300 | 1.0" | 2.0 |

| ASFP188 | 18 | 8 | 50 | 1.27 | 47.0 | 2500 | 1.5" | 3.0 |

| ASFP1810 | 18 | 10 | 50 | 1.62 | 54.2 | 3200 | 1.5" | 3.0 |

| ASFP1812 | 18 | 12 | 50 | 1.842 | 67.2 | 4000 | 1.5" | 3.0 |

| ASFP1815 | 18 | 15 | 25 | 2.27 | 37.5 | 5000 | 1.5" | 3.0 |

| ASFP1818 | 18 | 18 | 25 | 2.72 | 50.0 | 5500 | 1.5" | 3.0 |

| ASFP1818 | 18 | 18 | 50 | 2.77 | 100 | 5500 | 1.5" | 3.0 |

| ASFP1823 | 18 | 23 | 25 | 3.45 | 57 | 6800 | 1.5" | 3.0 |

| ASFP2412 | 24 | 12 | 50 | 3.37 | 110 | 6700 | 2.0" | 5.0 |

| ASFP2415 | 24 | 15 | 50 | 4.21 | 123 | 7800 | 2.0" | 5.0 |

| ASFP2418 | 24 | 18 | 38 | 5.04 | 130 | 10000 | 2.0" | 5.0 |

| ASFP2423 | 24 | 23 | 38 | 6.34 | 165 | 12500 | 2.0" | 5.0 |

| ASFP337 | 33 | 7 | 38 | 4.2 | NA | 8000 | 2.5" | 7.5 |

| ASFP3310 | 33 | 10 | 38 | 5.6 | NA | 11000 | 2.5" | 7.5 |

| ASFP3314 | 33 | 14 | 38 | 7.5 | NA | 15 000 | 2.5" | 7.5 |

| ASFP3323 | 33 | 23 | 38 | 14.0 | NA | 25000 | 2.5" | 7.5 |

Our engineer comes to your location to install our machines. We also provide the complete installation document which includes the instruction of operation also.

We will solve machine problems even after sale and provide you necessary services and also supply important spare parts for smooth working. We also provide support on phone.

We provide complete document that helps to understand machines design, installation, operation and maintenance. All our documents are according to GMP/CGMP standards.

- Adress: 3312/8, Phase-IV, Chhatral

- Phone: (+91) 999-825-2299

- E-mail: sparklersfilterpress@gmail.com aksharpharmamachinery@gmaill.com

- Weekend: from 10 am to 6 pm